More design options than you can think of. You aren’t limited to simple drilled holes and square cuts. You design the part to work the way you want it to and Cardinal will provide the fabrication techniques to make it so.

Fabrication Options

just to name a fewDeburring

Drilling

FormingCutting

Countersinking

Assembly

Milling

Mitering

NotchingPunching

Reaming

Routing

Silkscreening

Slotting

Tapping

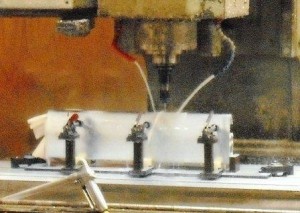

Fast Response To Design Changes.

Even the best thought-out designs sometimes need last minute

changes… moving holes, widening slots, cutting new angles. Thanks to

Cardinals’ multi-axis CNC matching systems, making a change has never

been easier.

Since little or no “hard tooling” is required,

you can move things around, change sizes or shapes-even in the middle

of a run -while eliminating additional tooling costs and work center

set-ups. It’s also a cost-efficient way to prototype and get your

product to market faster.

Our skilled operators make a few programming changes, swap a few cutter heads, and you’re off and running again.

You’ll also get greater accuracy and part-to-part repeatability that is mechanically consistent from start to finish.